|

www.sloopphyllis.com |

|

This is the story behind the 1907 Humber sloop that was to help fight two wars and join the search for the Loch Ness monster. |

|

|

|

Phyllis 1907. Loa 68ft, Beam16ft.4, Draft 7ft.4, Official Number 124785. Yard Number 60. Sail Number 26148. |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Updated: April 2016 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Sailing at South Ferriby |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Building of Phyllis. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

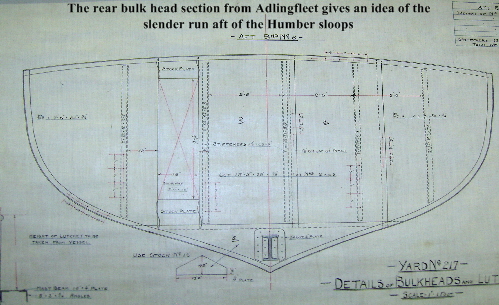

Extracts from the plans of "Adlingfleet" and "Zenitha" are by kind permission of The Hull Maritime Museum. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

James Barraclough who was an already well established Barton on Humber sloop owner along with his brothers Thomas, John and Joe with several sloops to his own name had "Phyllis" built in 1907 for the coal trade. Between them they had a run of five sloops built from 1904 to 1909 by WH Warren at New Holland on the banks of the River Humber; John William 1904, Alfred 1905, Phyllis 1907, Nancy 1907 and Elma A.B 1909. Phyllis was to be the second largest of the five sloops at 68ft Loa by 16.15ft beam and 7.4ft depth of hold, (fractions of a foot were given in tenths on paperwork for ease of tonnage calculations) the largest was "Elma A.B" built also for James Barroclough at 68ft Loa by 16ft 6" beam and 8ft depth of hold. These larger vessels had greatly increased capacity over the smaller but well established sloops that traded along the Sheffield and South Yorkshire Navigation and the Stainforth and Keady Canal out through Keadby lock into the Trent, those would loose out to the ability of the big sloops to use the New Junction opened in 1905 and carry over 150 tons compared to just 100 or less depending on water levels by the smaller sloops also through the New Junction. The route was also quicker, but the reward was the amount that was carried per trip through Goole using the Ouse to York, Hull or Grimsby. The new deep water docks at Immingham started in 1906 and to be opened in 1912 was also good news for the sloop owners. The Barracloughs would have known about any developments that would have favoured river transport and timed the building of the vessels to suit the demand. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

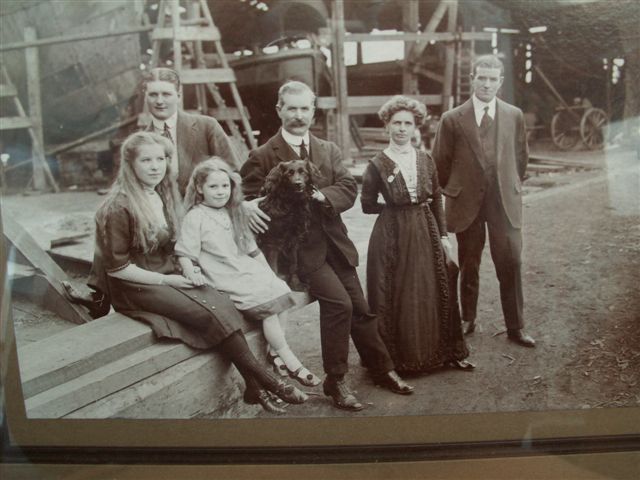

The Warrens. William Henry and second wife Ann Elizabeth. Son Fred, far right, designed Phyllis when he was 25 after serving time as draughtsman with Cochran's which was formerly Hamilton and Cooper's shipyard at Beverley. His father had also worked there as a shipwright. Ernest, 2 years younger, is far left and worked as yard joiner/carpenter and later as manager at New Holland. William's two daughters are at left of picture, Hilda and Mable. The name of the dog is unknown. (Picture courtesy of the Warren family) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Site created May 2009 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

By Kath Jones & Alan Gardiner. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| If anyone has any memories of working for James Barraclough or have a story about working on Phyllis or any of the Barraclough barges we would like to hear from you. If you have any comments or questions on the content of the site or would like to add something to it regarding any of the sloops we would also like to hear from you.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

At left is an example of the rivets and original 1907 plate that were uncovered in her hold area. The exceptionally good condition of her steelwork over 100 years later is a testimony to the quality of materials used by W.H Warren. Perhaps it was through the quality of ships like "Phyllis" that the yard succeeded under the management of William Warren after being closed down by two previous owners after only trading for a short time. The rounded bow and "D" iron strakes are shown well in the picture above right. Unlike the framework of the smaller variants of the Humber sloop that I had been used to seeing, Phyllis has, reflecting her different use and capacity, three additional stiffening "stringers" located on the inside of the bow, made of four inch rolled and riveted angle. A similar single stiffening stringer additionally runs the entire circumference of the vessel's interior riveted to every frame that are 20" apart in her mid section. The three external rubbing strakes on the bow are rolled five-inch 'D' iron rather than the rail iron sections that are found on inland vessels giving Phyllis a more streamlined look to her bow. The bottom rubbing strake running continually along the external circumference of the vessel just below her unladen waterline is also of 5" "D" iron, this is to prevent hull chafe when lying against walls and jetties. Her hull is constructed using 6 rows of riveted plates to make up each side of the hull instead of just 5 on later vessels making the shape of her hull easier to form and much stronger. With all those rivets she would have been expensive to build. Another significant characteristic of Phyllis as with similar Humber sloops of her time is her fine run that starts at the mid ships frame. At left is an example of the rivets and original 1907 plate that were uncovered in her hold area. The exceptionally good condition of her steelwork over 100 years later is a testimony to the quality of materials used by W.H Warren. Perhaps it was through the quality of ships like "Phyllis" that the yard succeeded under the management of William Warren after being closed down by two previous owners after only trading for a short time. The rounded bow and "D" iron strakes are shown well in the picture above right. Unlike the framework of the smaller variants of the Humber sloop that I had been used to seeing, Phyllis has, reflecting her different use and capacity, three additional stiffening "stringers" located on the inside of the bow, made of four inch rolled and riveted angle. A similar single stiffening stringer additionally runs the entire circumference of the vessel's interior riveted to every frame that are 20" apart in her mid section. The three external rubbing strakes on the bow are rolled five-inch 'D' iron rather than the rail iron sections that are found on inland vessels giving Phyllis a more streamlined look to her bow. The bottom rubbing strake running continually along the external circumference of the vessel just below her unladen waterline is also of 5" "D" iron, this is to prevent hull chafe when lying against walls and jetties. Her hull is constructed using 6 rows of riveted plates to make up each side of the hull instead of just 5 on later vessels making the shape of her hull easier to form and much stronger. With all those rivets she would have been expensive to build. Another significant characteristic of Phyllis as with similar Humber sloops of her time is her fine run that starts at the mid ships frame.  It was the run of the hull that differentiated a sloop hull from a keel hull although many believe that a sloop is the same as a keel apart from the sailing rig. Outwardly this is true of Sheffield size vessels or river sloops when only taking the deck equipment and general dimensions into account. This belief probably being brought about by the fact that in more modern times many Sheffield keels as with "Amy Howson" were re-rigged as sloops. The keels that traded seaward up until the 20th century had a longer run than the river craft. However I am safe in saying the vast majority of keels had very short runs to allow them to carry as much as possible, particularly in the shallow water of a canal. Keels traded seaward untill the 19th century but their dimentions and layout are difficult to establish accuratly. The sloops had the advantage of sailing ability and the length of the run dictated this, giving less drag and better handling in the often adverse conditions they were required to sail in. The inland trading Sheffield sloops inherited a proportionally shorter but also purposeful run to the hull from their larger seagoing cousins, how long a run depended on the orders of the owner to the builder. A sloop built with a long run carried less cargo, a sloop built with a short run carried more but didn't sail as well. It was a compromise for the Sheffield sloops that needed to use the locks and canals to trade their wares, which is why the Humber sloop apart from overall length boasted that bit extra beam and depth of hold, they could aford to have built-in sailing qualities that made them what they were, quick and relatively agile on the coast and in the lower reaches of the Humber carrying upward of 150 tons of cargo. I have used the drawing from "Adlingfleet" built 19 years after "Phyllis" to try and demonstrate this. After completion in August 1907 Phyllis was measured and her tonnage calculated for the Board of Trade by surveyor Mr W. Parnell. She was entered onto the British Ships Register and given the certificate number 58/1907. She was also given a sail number 26148 which we think refers to her Port Health Certificate. Phyllis was again calculated for the Department of War and Transport on 2nd October 1943 and re-certified on the British Ships Register as certificate number 40/1944 after having her engine fitted and prior to her being used by the War Office to tranship and store bombs that were being delivered into the Humber by American ships for the local airfields. Phyllis had a replacement engine fitted in 1962 and this is noted on her C.344B Certificate of British Registry, the engine was a 33 bhp air cooled Lister that has since been removed and shipped to the owners of "John William" another one of the Barraclough fleet and one of only two other Humber sloops that I know of to survive although no longer traditionally rigged, the other being "Annie Barraclough" now a houseboat moored near Lincoln. "John William" was in France at the time, her trip to France had taken it's toll and she now requiring a replacement engine and gearbox, I understand that she has now returned to England. A Gardner 6LXB of 180 HP is now powering Phyllis when there's no wind with matched gearbox and propeller. It was the run of the hull that differentiated a sloop hull from a keel hull although many believe that a sloop is the same as a keel apart from the sailing rig. Outwardly this is true of Sheffield size vessels or river sloops when only taking the deck equipment and general dimensions into account. This belief probably being brought about by the fact that in more modern times many Sheffield keels as with "Amy Howson" were re-rigged as sloops. The keels that traded seaward up until the 20th century had a longer run than the river craft. However I am safe in saying the vast majority of keels had very short runs to allow them to carry as much as possible, particularly in the shallow water of a canal. Keels traded seaward untill the 19th century but their dimentions and layout are difficult to establish accuratly. The sloops had the advantage of sailing ability and the length of the run dictated this, giving less drag and better handling in the often adverse conditions they were required to sail in. The inland trading Sheffield sloops inherited a proportionally shorter but also purposeful run to the hull from their larger seagoing cousins, how long a run depended on the orders of the owner to the builder. A sloop built with a long run carried less cargo, a sloop built with a short run carried more but didn't sail as well. It was a compromise for the Sheffield sloops that needed to use the locks and canals to trade their wares, which is why the Humber sloop apart from overall length boasted that bit extra beam and depth of hold, they could aford to have built-in sailing qualities that made them what they were, quick and relatively agile on the coast and in the lower reaches of the Humber carrying upward of 150 tons of cargo. I have used the drawing from "Adlingfleet" built 19 years after "Phyllis" to try and demonstrate this. After completion in August 1907 Phyllis was measured and her tonnage calculated for the Board of Trade by surveyor Mr W. Parnell. She was entered onto the British Ships Register and given the certificate number 58/1907. She was also given a sail number 26148 which we think refers to her Port Health Certificate. Phyllis was again calculated for the Department of War and Transport on 2nd October 1943 and re-certified on the British Ships Register as certificate number 40/1944 after having her engine fitted and prior to her being used by the War Office to tranship and store bombs that were being delivered into the Humber by American ships for the local airfields. Phyllis had a replacement engine fitted in 1962 and this is noted on her C.344B Certificate of British Registry, the engine was a 33 bhp air cooled Lister that has since been removed and shipped to the owners of "John William" another one of the Barraclough fleet and one of only two other Humber sloops that I know of to survive although no longer traditionally rigged, the other being "Annie Barraclough" now a houseboat moored near Lincoln. "John William" was in France at the time, her trip to France had taken it's toll and she now requiring a replacement engine and gearbox, I understand that she has now returned to England. A Gardner 6LXB of 180 HP is now powering Phyllis when there's no wind with matched gearbox and propeller.

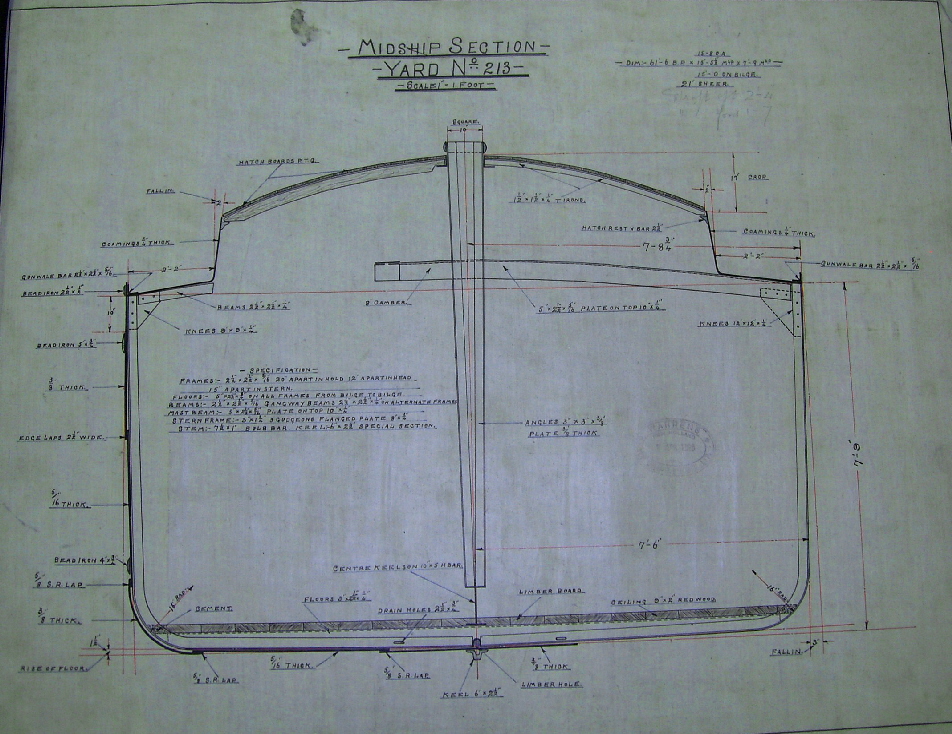

Note the curvature of the deck head that was built into the hull of the Humber sloops, this aided drainage and kept the after deck free of standing water. Phyllis's after deck was also wooden clad to assist with grip in heavy weather which was a commonly added feature on the large sloops.

An expansion drawing for "Adlingfleet" gives the cutting dimensions for each plate that makes up one side of her hull. It also indicates the plate thickness that is 3/8" (10mm) for the bottom and 5/16" (8mm) for above the chine as is Phyllis and seems to be an industry standard. The chine plates on "Phyllis" were doubled at the original build making them 11/16" (17mm) total thickness in that area. The hull of Adlingfleet, as can be seen from this drawing is made up of five rows of plate instead of six that the hull of "Phyllis" has giving her greater strength and making her an expensive ship to build. Being much later than "Phyllis" there are no strengthening stringers running inside the bow or down the length of the hull. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Interesting Links |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Humber Keel & Sloop Preservation Society. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Goole Waterways Museum. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Dutch Barge Association. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| In The Boat Shed. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Humber Packet Boats. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Leicester Trader. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Humber Yawl Club. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Brilliant Star | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Waterways of the HumberBy Christine Richardson. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Sheffield Ships. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sloop "Amy Howson" | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Articles |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| Above is the sectional view of a Sheffield size of sloop built at W.H Warrens. Yard #213 was "Zenitha" built in 1925 but shows characteristics that all the vessels have in the W.H Warren yard collection housed in the Hull Maritime Museum demonstrating how build techniques changed in Fred Warrens design of the vessels after "Phyllis" had been built in 1907. The emphasis had shifted from quality to cost as steel became favoured over wood, their rudders were now made from steel plate instead of wood and other methods were being used to cut cost. Competition between the shipyards on the Humber became stronger, the need to build seagoing sloops had ceased by 1914 allowing the hull design to be less robust. The biggest cost saving feature in the construction of the hull is the reduction in the number of plate lines, as with "Adlingfleet" this view of "Zenitha" shows there are only five rows of plates making up each side including the bottom of the hull instead of six as in the construction of "Phyllis". Although this reduces rigidity and the ability of the draughtsman to use subtle and gradual curves in his design that made the hull more efficient through the water it also reduces considerably the number of rivets and therefore time it would have taken to build the hull, which would of course make the vessels cheaper to produce. Another feature of design which made construction easier and quicker is also well demonstrated on the plan. In 1907 Fred Warren was designing the deck and the coaming (the side of the cargo hold) in two separate sections riveted together down the length of the deck using an angle iron section. Again this was expensive in material and labour so to further reduce the cost of the build the deck plate and the coaming were made from one piece of plate rolled into the desired shape as shown here. There was also a change in the method that the coaming was fastened to the head ledges (each end of the cargo hold). Instead of the traditional method of a pleasing curved and well riveted corner piece as in 1907 the corner section became more acute and on some vessels was a 90 deg butt joint provided less resistance to the stress's that were transferred through the ship, sometimes being the cause of cracking across the deck. It's obvious that these cost reducing alterations to the design of later vessels than "Phyllis" although producing a reduced quality of build, ensured the competitiveness and success of the yard for many years. Although I have specific references to vessels built with these later methods from the plans available at the Maritime Museum it is difficult to track down just when these cost saving methods of construction were introduced. Certainly shipyards other than W H Warren applied these methods and the latest vessel I have come across built using six plates is the keel "Onesimus" built by Joseph Scarr at Beverley in 1913, the same yard built "Amy Howson" a year later using only five plates. Could the later method of build have been or did it become an industry standard used in the construction of river craft? These methods are found in the construction of keels and sloops. Other questions raised are, Was the cheaper method of construction being used in 1907 and if so, why wasn't "Phyllis" built this way? .... Questions are still waiting to be answered, perhaps, "Phyllis" was one of the last steel sloops to be built to the same hull shape as her predecessors in an attempt to copy in steel the strength of hull and the efficient lines of the wooden Humber sloops of the 19th century. W.H Warren died in 1923 at the age of 62, Fred Warren died in 1930, Ernest Warren died in 1948. Thanks to all their skills the yard produced a range of vessels for local and military use until being sold out of the family by Peter Warren in 1962. |

|

The keel of "Phyllis" was laid down in 1907, two years before "Titanic". In 1907 Barbara Stanwyck, Frank Whittle and John Wayne were born. The great ship "Lucitainia" completed her record breaking crossing of the Atlantic in just five days. |

| [Home Page] [A Short History] [The Building] [Plate Pic] [Documents] [Sloop Plans] [The Rescue] [Phyllis at Work] [The Journey Home] [The Restoration.] [Square Rigged Sloops] [Gravel Sloops] [Barton Regatta] [Water Colour Sloop] [Back Under Sail] [The Clippers] [Picture Gallery] |